In Singapore’s fast-paced industrial and logistics environments, printing high-quality, durable labels is critical. At the heart of many industrial printing solutions is the thermal transfer ribbon—a product designed to deliver consistent, high-performance label printing using heat and advanced multilayered materials.

Although it may look like a simple plastic roll, the thermal transfer ribbon (TTR) is an essential printing product, packed with innovation. Used in a wide range of applications, it plays a key role in ensuring clean, readable barcodes, text, and graphics on labels that must withstand heat, abrasion, chemicals, and environmental exposure.

What is a thermal transfer ribbon?

A thermal transfer ribbon is a multilayered film roll used in thermal transfer printers to apply ink onto surfaces such as labels, tags, or packaging. When the ribbon passes through the heated printhead, the ink layer melts and transfers to the surface of the material—usually paper or synthetic film—creating a crisp, resistant print.

Each ribbon is carefully designed with specific layers to optimize print quality and printhead durability. These layers include:

- Backcoat: Protects the printhead by reducing friction and preventing static.

- Release layer: Controls the transfer of ink by managing how the heat separates the layers.

- PET carrier (polyester film): The structural backbone that holds all layers together during printing.

- Ink layer: Contains wax, resin, or a combination of both, depending on the label resistance required.

- Leader and trailer: Assist with printer calibration and prevent printhead damage when ribbons run out.

This multi-layer structure ensures durability, print definition, and optimal performance across various printers and label materials.

What is a thermal transfer ribbon used for?

Thermal transfer ribbons are used in thermal printing systems for producing durable, long-lasting labels across many sectors. They are especially suited to printing barcodes, product IDs, regulatory information, and traceability codes.

Key applications in Singapore include:

- Electronics manufacturing – component tracking and ESD label printing

- Pharmaceuticals – batch codes and compliance labeling

- Food industry – cold chain, packaging, and expiry date labeling

- Logistics & warehousing – shipping labels and inventory control

- Industrial – safety labels, product IDs, and high-resistance tags

These ribbons are essential where durability, precision, and resistance to moisture, heat, or chemicals are non-negotiable.

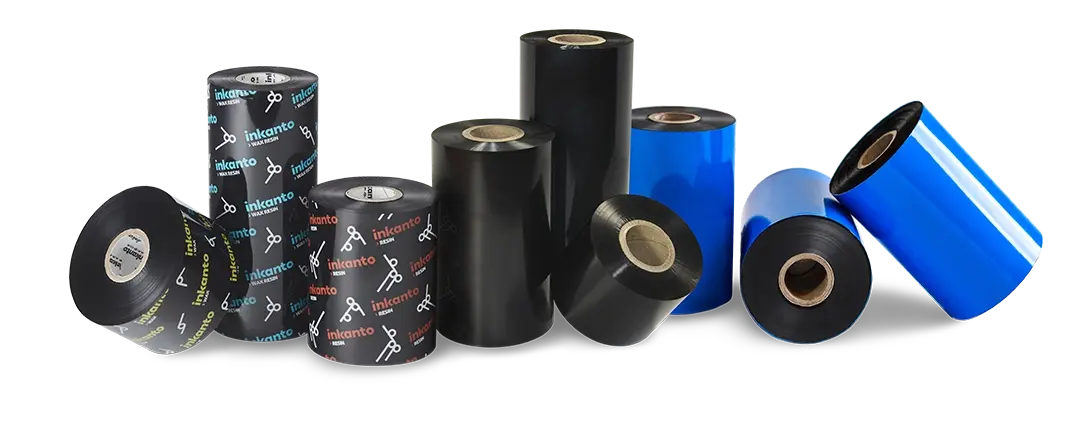

Types of thermal transfer ribbons

Not all ribbons are the same. The right type depends on the material you’re printing on and the environmental conditions your labels will face. Here’s an overview of the main types used in Singaporean industries:

Wax ribbons – For short-term, paper-based printing

- Ideal for coated and uncoated paper labels

- Most cost-effective ribbon type

- Suitable for retail, shipping, or temporary product labels

- Limited resistance to abrasion or chemicals

Resin ribbons – For extreme durability and resistance

- Designed for synthetic materials (e.g., PET, PP, PE)

- Resistant to solvents, heat, water, and mechanical stress

- Recommended for industrial, medical, and chemical applications

- More expensive but delivers exceptional print durability

Wax-resin ribbons – Balanced quality and resistance

- For mixed materials: coated paper, synthetic films

- Offers better resistance than wax, at a lower cost than pure resin

- Common in logistics, retail, and healthcare labeling

- A great option for mid-term use in moderately demanding environments

Textile resin ribbons – Specialized for fabric printing

- Compatible with common textile materials used in clothing tags

- High durability for industrial laundering, ironing, and dry-cleaning

- Ideal for uniforms, workwear, and textile product labels

Best practices for choosing and using thermal ribbons

To ensure optimal print results and prolong the life of your thermal printer, follow these key recommendations:

- Choose the correct ribbon type based on your label material and application

- Check printer compatibility – match the ribbon to the printhead technology (flat-head or near-edge)

- Adjust printer settings – heat and speed settings directly impact print quality

- Store your ribbons properly – avoid moisture, direct sunlight, and high heat

- Use ribbons from a trusted supplier to ensure consistent performance and avoid damage to your print system

Comparison of thermal transfer vs. direct thermal printing methods

When choosing the right printing technology for your labels, it’s essential to understand the difference between thermal transfer printing and direct thermal printing. While both use heat and a printhead, their methods and materials differ significantly.

Thermal transfer printing uses a ribbon coated with ink (typically wax, resin, or a mix) that is transferred onto the label material. This method is ideal for applications requiring durable, long-lasting prints, such as in industrial, pharmaceutical, or logistics environments. It offers excellent resistance to moisture, chemicals, abrasion, and heat.

Direct thermal printing, on the other hand, does not use a ribbon. Instead, the heat-sensitive label itself darkens when heated by the printhead. While this method is cost-effective and requires fewer consumables, it is only suitable for short-term applications. Labels printed this way are more vulnerable to fading, abrasion, and environmental exposure.

In short:

- Use thermal transfer for durable, high-quality labels on a variety of materials.

- Use direct thermal for temporary labeling in controlled environments.

Which printers are compatible with thermal transfer ribbons?

Thermal transfer ribbons are compatible with most thermal printers designed for transfer printing, not direct thermal. Models from manufacturers like Zebra, TSC, Sato, Intermec, and Citizen are commonly used across Singapore and support these ribbons for high-volume industrial printing.

Always confirm the ribbon format (roll diameter, core size, ribbon side in/out) and ribbon layer configuration required by your printer model.

Discover the right ribbon for your application

Understanding the layers, types, and applications of thermal transfer ribbons is key to choosing the right product for your printing environment. Whether you need a wax ribbon for warehouse labels, a resin ribbon for lab-grade durability, or a textile ribbon for industrial garments, ARMOR-IIMAK Singapore provides expert guidance and proven ribbon solutions tailored to your sector.

Our ribbons are designed to perform in Singapore’s industrial and commercial ecosystems—delivering reliable printing, long-lasting results, and high operational efficiency.