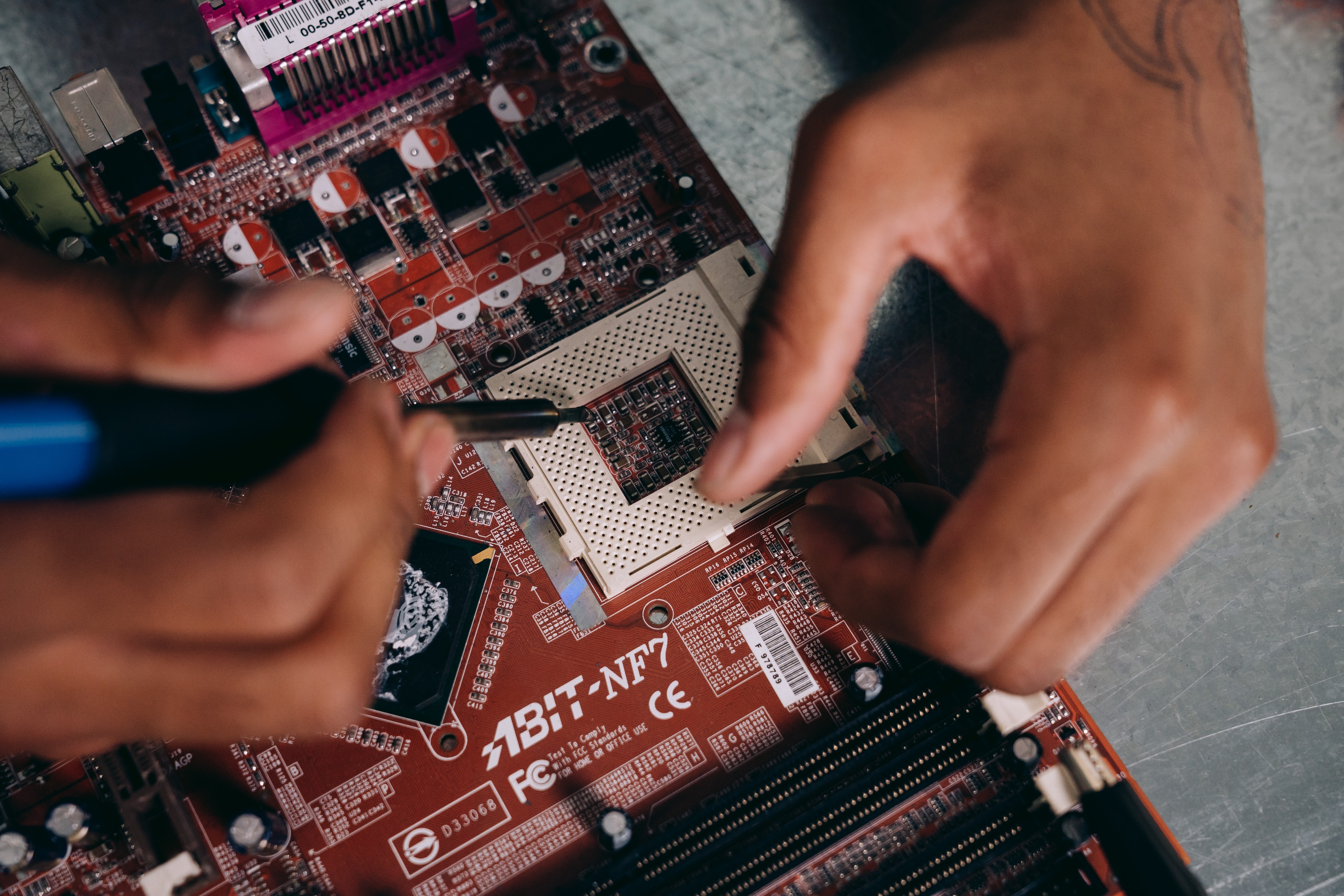

One of the largest Taiwan consumer electronics manufacturers had multiple research and development (R&D) and manufacturing facilities across China specialized in manufacturing computer hardware, mobile phones, networking equipment, monitors, and other consumer electronics-related products. With continuous improvement and innovation over the past 20 years and dedication to offering various quality products and services, the company grew quickly, especially in China’s market as one of the largest consumer markets in the world.

The challenge

The variety of stages from designing, manufacturing, and distributing of goods into the market, resulted in increasing demand in terms of traceability, ascribable of the product in the production stage, and the information of the products, the ink, and the substrates chosen play a significant role in ensuring all critical information are well-printed on the substrate and able to withstand physical resistance throughout their lifecycle.

Considering the wide array of substrates with different specifications required, they were looking for a better solution to ensure their ongoing effort to excellence with a healthy dose of profitability in the long term. They tried multiple ribbons but did not meet their minimum requirement – specifically on coated paper and synthetic paper. This clearly reflects the action needed to ensure the traceability of the products from A to Z.

The Taiwan consumer electronics manufacturer list out their requests to our partner in China:

- The versatility of the ribbon – One product for all substrates they are currently using

- Applicable with their printer specification – Zebra 105SL 300DPI and 600DPI

- Excellent printing results and stability of the quality

- Able to withstand aggressive production processes due to the automated production chain and the entire product lifecycle

The Solution

ARMOR-IIMAK and our partner in China have answered all their questions by offering two kinds of inkanto® ribbons. Each of the four production lines in China was replaced with inkanto® ribbons, AXR 7+, and APR 6, which matched the stringent specifications they mentioned.

Why AXR 7+, not others?

- AXR 7+ is capable of withstanding scratches and smudges that are on the printed label applied on the hardware casing such as laptop case, graphic card and the product information labelling on the packaging box of the finished goods

- AXR 7+ shows perfect barcode scanning and readability after conducting multiple scientific tests. The reason behind the test is to ensure traceability of the product from the production cycle to the hand of the end-user and guarantee the printed label must be permanently visible throughout the product lifecycle

- Good resistance to hot temperature when the label is applied in the extremely hot working environment

And why APR 6?

- The versatility and excellent quality even print on a wide range of substrates from rough, coated, or even synthetic paper, mainly applied within the production cycle

- Able to print at low heat setting with 16ips (400mm/s) insane high-speed printing

Why ARMOR-IIMAK and our partner?

Besides meeting the challenges and requirements, ARMOR-IIMAK and our partner can showcase the following:

- Fast support and response for after-sales service from ARMOR-IIMAK’s partner

- A century-solid background of the company mainly supplying only ribbon

ARMOR-IIMAK, together with our partner’s sales team and technical team in China dropped multiple visits with a range of ribbons at the early stage of replacing their current ribbon with inkanto ribbon. They spent a week on-site to conduct the test to ensure we were there to support them when any technical issue arises, and it turned out perfect. It reflects the professionalism and high quality of our rapid response capability.

Our dedicated sales team and partners were 100% confident that the inkanto ribbon range provides a comprehensive solution that satisfies all the challenging requirements of the company, resulting in 10 % sqm increase of the resin ribbon, AXR 7+ and 25% sqm increase of wax-resin, APR 6.

In terms of competitors’ service and after-sales response capabilities are not good as ARMOR-IIMAK.

Stability of the ARMOR-IIMAK’s product is the key to success due to the lesser down time of the machines.