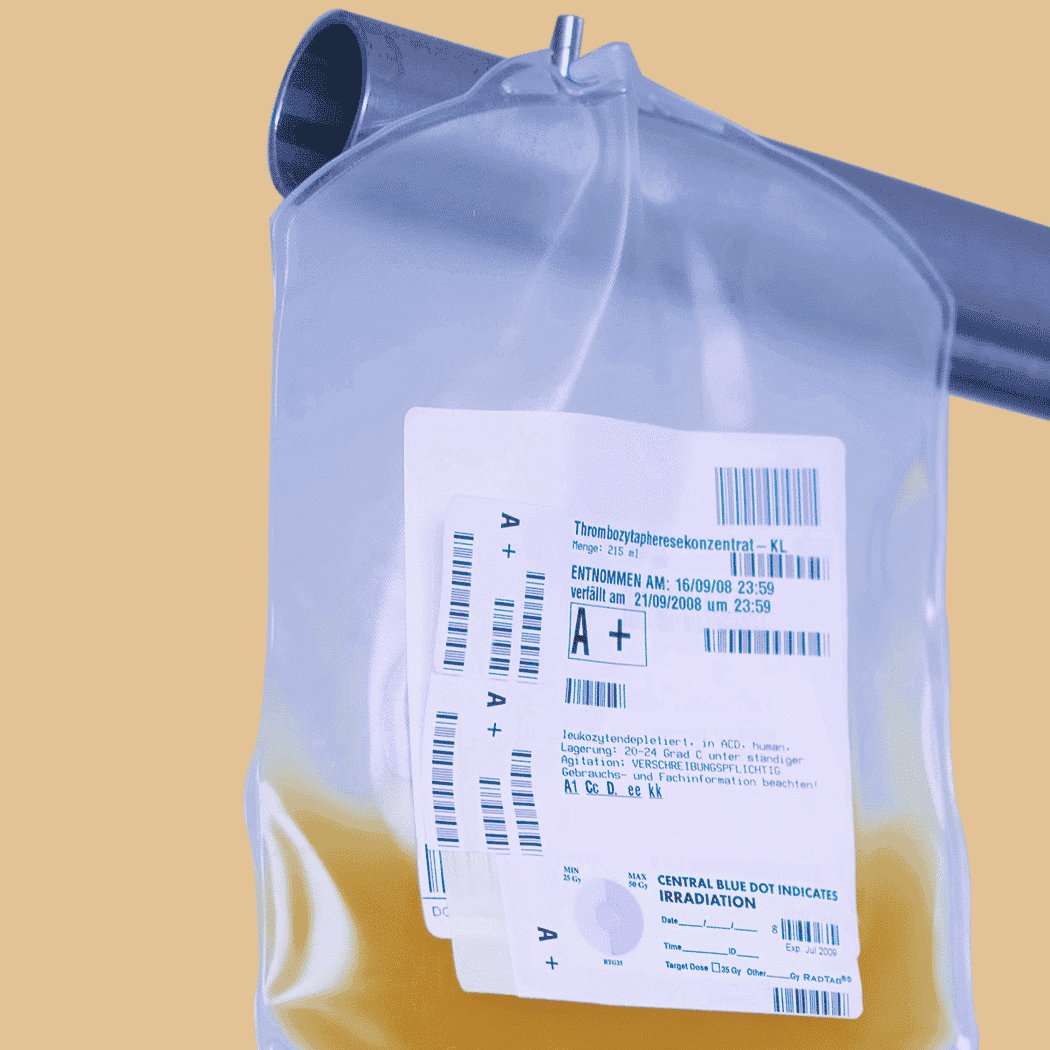

Labeling Blood and IV bags

Patient safety is at stake. Imagine: An accident victim has lost a lot of blood. Some blood bags have illegible labels in the hospital, so available blood cannot be used. Will there be more blood bags available in time?

This extreme example demonstrates how the legibility of the printed information of blood donation labels can be of life-or-death importance.

To ensure patient safety, blood bag labels need to stay intact through their lifecycle. This is because patients expect to get the correct type of blood without any worries of mix-ups or contamination due to labeling issues.

Labels must stay intact to ensure the traceability of each blood bag. Labels on blood donation bags provide vital information, such as donor number, blood type, and expiration date. The various blood treatment processes (such as centrifugation), the sterilization by autoclave (100 to 140°C / 212 to 284°F) and the various stages of storage (up to -50°C/-58°F) and transport subject the ink to high levels of stress. A damaged barcode or blood group would make the blood bag unusable.

These labels are held up to strict requirements as they hold sensitive information; some examples of this include:

- To ensure patient safety, blood donation labels carry information about the blood donor, such as donor identification, blood type, and expiration date.

- The blood bags and their labels must endure harsh conditions during blood component processing and storage.

- Printed information on the labels needs to stay legible to ensure patient safety.

Why using thermal transfer technology for this application ?

So that the printing on the label remains intact throughout the lifecycle of the blood bag, it is recommended to use the resin-based ribbons which combine:

- excellent print finish, even for small barcodes such as Datamatrix or 2D

- resistance to the cold, to the steam of the autoclave, and abrasions

- ability to print on all label materials generally used on blood bags (coated paper and synthetic materials).

It is also possible to print primary production data directly onto the bag using black or colored ribbons for near-edge printers.

For this application, we recommend the following products: